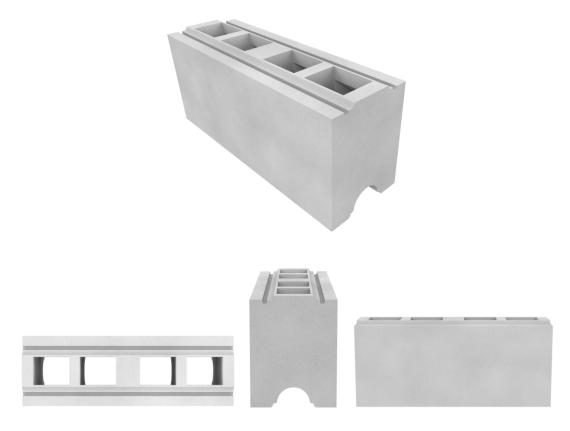

600×250×100mm (Square Hole) High-Precision Desulfurized Gypsum Hollow Block

600×250×100mm (Round Hole) High-Precision Desulfurized Gypsum Hollow Block

600×250×200mm High-Precision Desulfurized Gypsum Hollow Block

Product Introduction

The Hanmero high-precision desulfurized gypsum hollow block is made from desulfurized building gypsum and fly ash as the main raw materials, with the addition of alkali activators, setting retarders, fibers, and other components. After mixing with water, it is stirred, mechanically formed, and dried to create gypsum building products. The blocks have precisely positioned tenons and mortises on the top and bottom, and grooves for connecting reinforcement bars and pipeline channels in the horizontal direction, making them suitable for assembly construction. This product is referred to as Hanmero high-precision block, and it is available in two versions based on moisture resistance: the regular type and the moisture-resistant type.

Product Specifications:

| Specifications and Dimensions(mm) | Items | Standard Block | Auxiliary Specification Block | |

| 1/2 Block | Solid Block | |||

| Wall thickness | 30、40 | 30、40 | - | |

| Length (L) | 600 | 298 | 600、298 | |

| Height (H) | 250 | 250 | 250 | |

| Thickness (T) | 100 | 100 | 100 | |

| Note: Other specifications and dimensions can be manufactured as per design requirements. | ||||

Key Performance Indicators:

| Key Performance Indicators | Item | Unit | Performance Indicators | |

| Standard Type | Moisture-Resistant Type | |||

| Apparent Density | Kg/m³ | ≤700 | ||

| Breaking Load | N | 2000 | ||

| Softening Coefficient | - | ≥0.6 | ||

| Water Absorption (2h) | % | - | ≤5.0 | |

| Moisture Content | % | ≤10 | ||

| Compressive Strength | MPa | ≥5.0 | ||

| Radioactivity | - | Internal Radiation Index IRa≤1.0 | ||

| External Radiation Index Ir≤1.0 | ||||

Dimensional Deviation:

| Dimensional Deviation(mm) | Items | Permissible Deviation |

| Length (L) | ±1 | |

| Height (H) | ±1 | |

| Thickness (T) | ±0.8 | |

| Minimum Wall Thickness Between Holes and Between Hole and Wall | ≥25.0 | |

| Flatness | <0.8 | |

| Note: The permissible deviation values are based on Hanmero high-precision blocks of size 600×200×250mm. | ||

Application Scope:

This product is suitable for seismic fortification intensity levels of 8 degrees and below, for the construction, renovation, and expansion of partition walls in both residential and industrial buildings.

Product Advantages:

Gypsum blocks are not only a highly efficient building material but also a comprehensive green building material, fully in line with the principles of sustainable development in the circular economy. At the same time, gypsum building materials are also very user-friendly for interior spaces.

1.Safety

The final hydration product of gypsum materials is calcium sulfate dihydrate, and according to data, the temperature at which its two crystallized water molecules decompose is approximately 1070-1700°C. When exposed to fire, the temperature cannot rise until all of the crystallized water has been decomposed. During the decomposition process, the large amount of water vapor generated can help block the spread of flames. Foreign experiments show that the decomposition speed of calcium sulfate dihydrate crystals in a 6mm thick wall is about 15 minutes, and the decomposition time is around 4 hours, providing valuable time for evacuation and firefighting during a fire. Even more valuable, during the decomposition of crystallized water, if the indoor walls have not yet reached the combustion point, the fire can be extinguished in time, protecting the indoor property from fire damage.

2.Comfort

Comfort refers to having "warmth" and "breathing function."

Since gypsum is used to make building materials, its hydration time is generally between 0.6h-0.8h. After hydration and hardening, a large amount of free water evaporates, leaving many voids in the product, thus forming a porous material with a thermal conductivity coefficient of 0.2-0.28w/m.k, similar to that of wood. People like wooden floors, wooden walls, and even wooden panels because they are warm materials that make people feel warmer and more comfortable. Gypsum materials also have similar functions to wood. After the 1929 Kanto earthquake in Japan, secondary fires destroyed their wooden houses. They learned from American experience and quickly transformed wood into gypsum wall materials with warmth and fire-resistant properties. Currently, gypsum wall materials are used in nearly all partition walls of homes in the U.S. and Japan. They are also very common in Eastern Europe and Asia, with over 100 countries using gypsum building materials indoors.

The "breathing" capability of gypsum materials comes from their porosity. These voids absorb moisture when the indoor humidity is high, and release moisture when it is dry, automatically adjusting the indoor humidity and creating a comfortable environment.

3.Complete Functionality

Can comprehensively meet indoor functional requirements

Gypsum materials are suitable for ceilings, walls, and floors, with various types and combinations to meet the demands for insulation, fire resistance, soundproofing, water resistance, flexible partitioning, and decoration.

4.Convenient Construction

Gypsum building materials represent a significant innovation for interior construction

With dry construction methods, interlocking joints, and no need for plastering on both sides, final finishes can be applied just 12 hours after the wall is completed, saving time and materials.

5.High Cost Performance

Because it is a lightweight material, its weight is only half that of conventional building materials, reducing the load and stress on the entire structure, decreasing the need for reinforcement, and lowering the overall cost.

6.Green and Eco-friendly

Gypsum is a low-radiation mineral that does no harm to the human body

7.Excellent Seismic and Crack Resistance

Unlike silicate-based products that are gel-like and crack with temperature fluctuations, gypsum forms crystals upon hydration.

It does not crack, maintains structural stability, and deforms synchronously with the building structure.

The main products can be mass-produced, with supporting products forming a comprehensive system from design to construction and quality requirements. The modularization of gypsum building materials, especially for partition wall materials, is developing rapidly, with broad prospects.