Introduction to High-Precision Desulfurized Gypsum Hollow Block

1. Project Overview

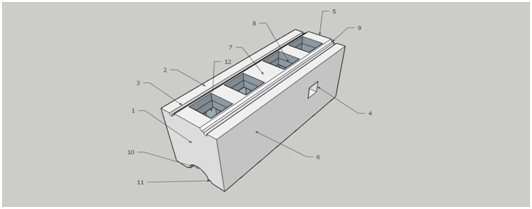

The high-precision gypsum block is a building material made primarily from desulfurized gypsum and fly ash, supplemented with fibers and modifiers. These components are mixed with water, mechanically shaped, and dried to create a rectangular gypsum product. The blocks are equipped with precise positioning tongues and grooves on the top and bottom, as well as horizontal tie bar grooves and pipeline channels. They are primarily used for modular partition walls. See Figure 1 for a schematic diagram of the high-precision gypsum block structure.

Figure 1 Schematic Diagram of High-Precision Gypsum Block Structure

1. End Wall

2. Transverse Concave Rib Reinforcement

3. Structural Horizontal Bidirectional Tie Bar Groove

4. Alignment Assembly Hole

5. Upper Tenon Groove Tongue

6. Side Wall

7. Thickened Reinforcement Rib

8. Vertical Pipeline Hole

9. End Reinforcement Rib

10. Horizontal Pipeline Channel

11. Bottom Tenon Groove Socket

12. Vertical Corner Concave Rib Reinforcement Inside Cavity

The high-precision gypsum block and wall technology have unique features, including the top and bottom tongue-and-groove structure, high accuracy of finished blocks, and flexible design dimensions. Compared to traditional panels, the assembled wall system exhibits superior crack resistance, addressing common quality issues of various wall panels. This creates significant growth opportunities for interior partition wall applications.

The modular wall technology developed through this project promotes comprehensive utilization of industrial by-products, advancing construction industrialization. It ensures the sustainable development of the construction industry in China and aligns with the current technical requirements and developmental direction of prefabricated buildings in the country.

2. Performance Indicators and Technical Features

2.1 Performance Indicators of High-Precision Gypsum Blocks

Table 2.1.1 Dimensional Requirements (Unit: mm)

| Item | Requirement |

| Length | ±0.8 |

| Height | ±1 |

| Thickness | ±0.8 |

| Minimum wall thickness between holes and between holes and plate surfaces(l1) | ≥25.0 |

| Flatness | <0.8 |

Table 2.1.2 Key Performance Indicators

| Item Name | Unit | Technical Indicator | |

| Dry Apparent Density | kg/m³ | Hollow Block, 30mm | ≤600 |

| Hollow Block, 40mm | ≤800 | ||

| Compressive Strength | MPa | ≥3.5 | |

| Fracture Load | N | 2000 | |

| Moisture Content | % | ≤12 | |

| Thermal Conductivity | W/(m·K) | ≤0.26 | |

| (2h) Moisture-resistant type | Water Absorption | ≤10 | |

| Softening Coefficient | ≥0.6 | ||

2.2 Specialized Gypsum Bonding Mortar

Specialized gypsum bonding mortar is made from gypsum powder, latex powder, water-retaining agents, and anti-cracking fibers mixed in specific proportions. Its performance indicators include apparent density, compressive strength, bonding strength, setting time, and water retention rate. See Table 2.2 for detailed requirements and test results.

Table 2.2 Key Physical Performance Indicators of Specialized Gypsum Bonding Mortar

| Item | Unit | Requirement | |

| Apparent Density | kg/m³ | ≤1500 | |

| Water Retention Rate | % | 80 | |

| Fineness | 1.18mm | 10 | |

| 150μm | ≤25 | ||

| Setting Time | Initial Setting | min | ≥25 |

| Final Setting | ≤120 | ||

| Dry Strength | Compressive Strength | MPa | ≥5.0 |

| Flexural Strength | MPa | ≥5.0 | |

| Tensile Bonding Strength | MPa | ≥0.70 | |

2.3 High-Precision Gypsum Block Modular Lightweight Partition Walls

The modular lightweight partition wall is constructed using high-precision gypsum blocks and specialized gypsum bonding mortar. Surface finishes may include putty, paint, decorative panels, or tiles.

Key performance indicators for high-precision gypsum block modular lightweight partition walls should meet the requirements shown in Table 2.3.

Table 2.3 Key Performance Indicators of High-Precision Gypsum Block Modular Lightweight Partition Walls

| Item | Unit | Requirement | |

| Hanging Load Capacity | N | The load is 1000N and left for 24 hours, and there is no crack with a width of more than 0.5mm on the board surface | |

| Impact Resistance | Times | After 5 times of impact resistance test, there is no crack on the plate surface | |

| Weighted Sound Insulation | dB | Panel Thickness <15mm | ≥35dB |

| Panel Thickness ≥15mm, Wall Thickness 30mm | ≥45dB | ||

| Panel Thickness ≥15mm, Wall Thickness 40mm | ≥48dB | ||

| Thermal Resistance | Meets Design Requirements | ||

| Fire Resistance Limit | h | 2 | |

3.Technical Performance Features

High-precision gypsum block modular lightweight partition walls are widely used in non-load-bearing interior walls of residential and general industrial buildings. Compared with other wall technologies, they offer the following advantages:

1.Precise Dimensions and Excellent Shrinkage Properties

High-precision gypsum blocks are primarily made from gypsum and fly ash using a "vertical mold forming and hydraulic lifting" process, with forming equipment controlled by digital automation. The blocks are standardized, precise in appearance, and exhibit low drying shrinkage, effectively eliminating issues such as hollowing and cracking in traditional interior partition walls, ensuring superior wall quality.

2.Interlocking Tongue-and-Groove Joints for Stability

The top and bottom surfaces of the gypsum blocks feature tongue-and-groove joints, which interlock to provide horizontal shear resistance and impact strength, ensuring structural integrity and reliability of the walls.

3.Dry Construction with High Efficiency

The gypsum blocks employ a dry construction method with thin seams bonded by specialized gypsum adhesive, significantly enhancing construction efficiency.

4.Smooth Walls Without Plastering

High-precision gypsum blocks are prefabricated in factories using automated production lines, ensuring high quality and precision. The assembled modular walls meet the flatness and verticality requirements specified in the Code for Quality Acceptance of Building Decoration and Finishing Engineering (GB 50210-2001). The walls can directly receive a putty coat without requiring plastering, thus avoiding wet construction processes.

Figure 4.1 Engineering Application of High-Precision Gypsum Block Modular Lightweight Partition Walls

5.Eco-Friendly, Energy-Efficient, and Recyclable

The blocks use by-product gypsum and fly ash as primary raw materials, achieving comprehensive utilization of industrial solid waste. The production process generates no wastewater, waste gas, or residue, and the blocks are non-toxic and harmless. After disposal, they can be crushed, calcined, and recycled, enabling resource reuse.