Review of Concrete Admixture

Concrete admixtures are ingredients consisted of in the concrete mix prior to or during mixing to modify particular properties of the concrete, either in its newly mixed or hard state. These ingredients can improve workability, strength, setting time, and sturdiness of concrete, making them vital in modern building and construction methods.

Attributes of Concrete Admixture

Workability Enhancers: Boost the flow and handling of the concrete mix, lowering the initiative needed for putting and finishing.

Accelerators: Speed up the setup and reinforcing process of concrete, allowing quicker type removal and faster job progress.

Retarders: Slow down the hydration procedure, offering more time to deliver and put the concrete, particularly useful in hot weather or big pours.

Water Reducers (Plasticizers): Reduce the quantity of water called for to attain a provided downturn, causing higher stamina and much better longevity.

Superplasticizers: An extra potent variation of water reducers, permitting considerable water decrease without loss of workability.

Air-Entraining Agents: Introduce little air bubbles right into the concrete to improve freeze-thaw resistance and improve workability.

Rust Preventions: Safeguard embedded metals such as support bars from corrosion, extending the lifespan of the concrete framework.

Coloring Representatives: Made use of to transform the color of the concrete, preferred in architectural applications.

Waterproofing Admixtures: Boost the impermeability of concrete, making it more immune to water infiltration and leakage.

Fiber Reinforcements: Include fibers right into the mix to raise tensile sturdiness and lessen splitting.

Applications of Concrete Admixture

Admixtures are widely utilized throughout different building and construction markets:

Residential Structure: To guarantee durability and lengthy life of home structures, wall surface areas, and floorings.

Commercial and Business Projects: For high-performance concrete in frameworks, bridges, and freeways.

Framework Development: In the construction of dams, passages, and various other large-scale projects needing particular concrete buildings.

Historic Repair: To match the original buildings of historic concrete and masonry while improving longevity.

Environmental Projects: In green building techniques, where sustainability and marginal ecological impact are priorities.

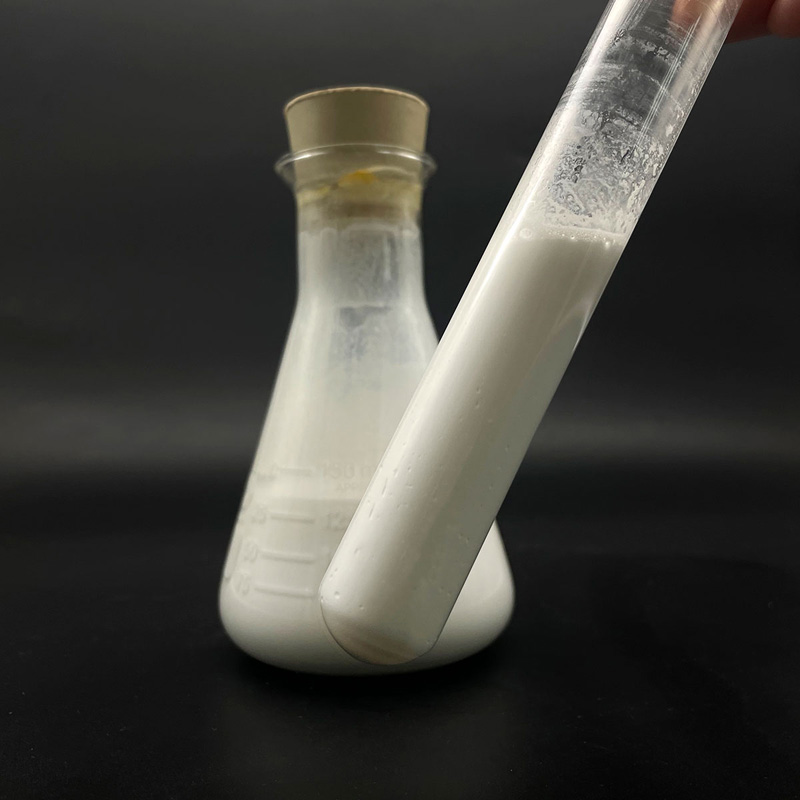

water-based release agent is an environmentally friendly and highly efficient chemical reagent used to prevent materials from adhering to the surface of molds, which is widely used in the manufacture of concrete products and composites. The following are some of the main features and uses of Tongrun Waterborne Mould Release Agent:

Concrete release agents

Main features

Environmentally friendly and non-toxic: water-based release agent does not contain organic solvents, is pleasant to the environment and is safe to use.

Easy to release: Effectively reduce the adhesion between the material and the mold; easy to release the mold with a smooth surface.

Strong weather resistance: adapts to various temperature and humidity conditions, stable performance.

Economical and efficient: low dosage, low cost, prolonging the life of the mold and saving the maintenance cost.

Usage

A water-based mold release agent is suitable for the release of precast concrete, wall panels, large cement components, etc. It is especially suitable for various products of lightweight concrete.

Concrete precast house after mould release

Advantages

Environmentally friendly and non-toxic:

The use of water as a solvent significantly reduces volatile organic compound (VOC) emissions.

Complies with strict environmental regulations (e.g., REACH, RoHS).

No toxic fumes are released during production or use, reducing environmental and human hazards.

Easier disposal of waste, reducing the ecological burden.

Easy mold release:

Water in contact with the mold evaporates quickly, and the active ingredients can soon form a uniform lubricating film, reducing product residue or surface defects.

The formula contains anti-rust components, which can inhibit mould oxidation and prolong service life, while improving product surface finish and reducing subsequent processing requirements.

Economical and efficient:

Usually can be diluted with water, and a small amount of stock solution can meet the demand and save cost.

Extends the life of the mold, reduces the frequency of replacement and saves long-term costs.

Usage

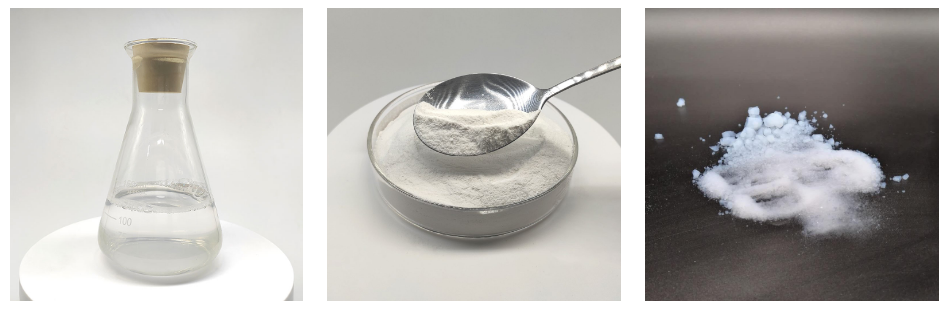

Recommended dosage: 50-100g/m³; exact dosage to be determined by test results.

Usage: It is best to dilute the original water-based mold release agent with 3-5 times of water and mix well.

Use a brush or spray to apply the diluted solution evenly on the surface of the mold, and wait for 5-10 minutes before pouring.

Concrete precast house after mould release

Storage and Transportation

Packing: water-based mold release agent: packing specification is 20kg/barrel, 25kg/barrel, 200kg/barrel, non-toxic and non-flammable, and can be transported as common goods.

Storage: Store in a cool and dry place; avoid rain and moisture. Shelf life is 24 months.

Precautions

This product is designed for the release and efficient production of lightweight concrete and other cementitious products.

The use of Tongrun water-based mold release agents can significantly improve production efficiency, reduce environmental pollution, and, at the same time, reduce production costs, which is an indispensable tool in the modern manufacturing industry.