Overview of concrete fiber

Fiber used in construction projects is a thin and long material with an aspect ratio of generally more than 100, and has a certain tensile strength (also called breaking strength), elastic modulus (also called initial modulus) and ultimate elongation (also called breaking elongation). The fibers used in construction projects mainly refer to short-segment discontinuous fiber materials that can be evenly distributed in concrete and can strengthen the concrete structure.

According to the different fiber materials used, they can be divided into: natural fibers or artificial fibers; organic fibers or inorganic fibers, etc. Specifically, they can be divided into natural organic fibers (various hemp fibers, wood pulp fibers, coconut shell fibers (collectively referred to as cellulose fibers) and animal bristles, etc.); natural inorganic fibers (asbestos fibers, needle-shaped wollastonite, etc.), artificial organic fibers (also called synthetic fibers: polypropylene fibers, polyacrylonitrile fibers, polyvinyl alcohol fibers, polyester fibers, polyamide fibers, ultra-high molecular weight polyethylene fibers, etc.), and artificial inorganic fibers (metal fibers, glass fibers, basalt fibers, mineral wool fibers, and carbon fibers, etc.). According to the different elastic modulus of the fiber used, that is, whether the elastic modulus of the fiber is higher or lower than the elastic modulus of the matrix it is mixed with, it can be divided into high elastic modulus fiber and low elastic modulus fiber; according to the different matrix materials it is mixed with, it can be divided into: fiber for cement concrete, fiber for mortar (cement paste), fiber for asphalt concrete, etc.

Fiber concrete can be regarded as a concrete compounded with a certain amount of short, uniformly dispersed, and discontinuous fibers added to ordinary concrete. The combination of fiber and concrete matrix improves the inherent weaknesses of concrete and has a multi-faceted impact on the performance of concrete. The improvement of the crack resistance and durability of fiber concrete is of great significance to the construction of high-quality, beautiful and durable projects.

The role of fiber in concrete

Including fiber to concrete can increase the strength and split resistance of the material, and at the same time has a specific impact on the strength and rigidity of concrete

Boost the tensile toughness of concrete

The stamina of concrete generally comes from the cement and accumulation in the mixture. The tensile strength of concrete is extremely reduced. Adding a proper amount of fiber can make concrete have better tensile toughness, thus boosting the total strength of the concrete structure.

Enhance the sturdiness of concrete

The fiber in concrete can enhance the residential or commercial properties of microcracks in concrete, minimize the water leaks in the structure and air permeability in concrete, boost the frost resistance and sturdiness of concrete, and thus extend the service life of concrete.

Boost the influence performance of concrete.

After adding fiber, the energy absorption capability of concrete can be enhanced, therefore improving the influence performance of concrete and minimizing the degree of stamina reduction.

Types of fibers

Steel fiber

Metal fiber is a standard fiber contributed to concrete, such as steel fiber, aluminum alloy fiber, and so on. They have high toughness and large ductility. After adding them to concrete, they can enhance the seismic resistance and crack resistance of concrete, yet steel fiber is prone to rust.

Synthetic fiber

Artificial fiber products have good deterioration resistance and alkali resistance, mainly polypropylene fiber and nylon fiber, and so on. The addition of these fibers can efficiently enhance the fracture resistance and bending and tensile resistance of concrete, thus improving the overall performance of concrete.

Glass fiber

Glass fiber is cheap and is included big amounts. It is made use of greater than iron cable. It can boost the fracture resistance and impermeability of concrete and is challenging to corrosion.

The result of fiber on concrete toughness

The impact of fiber on concrete stamina generally consists of the following aspects:

Fiber type and size

Fibers of different types and sizes have various impacts on the stamina of concrete. Generally speaking, the longer the fiber length, the greater the result on the stamina of concrete.

Fiber enhancement

The quantity of fiber included likewise has a wonderful impact on the strength of concrete. Inadequate will certainly have virtually no result, while too much might cause the strength of concrete to lower.

Fiber circulation

Irregular circulation of fibers might trigger the strength of concrete to reduce, so when adding fibers, it is needed to pay attention to the full mixing of concrete and fibers.

Applications of Concrete Fiber

Building and construction: Used in slabs, pavements, bridge decks, and precast elements to raise durability and decrease upkeep.

Roadways and Freeways: Improves toughness and decreases the threat of fractures and rutting.

Industrial Floors: Gives resistance to heavy tons and influence in storehouses and manufacturing facilities.

Repair: Ideal for overlays and repair services where rapid stamina gain and very little downtime are needed.

Residential Projects: Made use of driveways, patio areas, and walkways to stop fracturing and improve visual appeals.

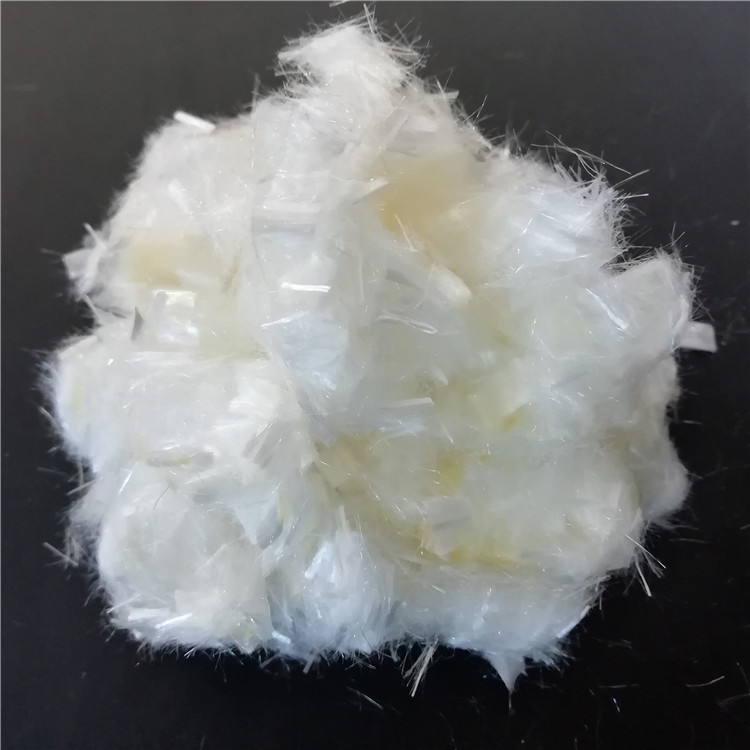

Introduction: Polyvinyl alcohol fiber has high tensile strength and modulus due to its resistance to acid and alkali, aging, corrosion, and other properties.

Corrosion, UV resistance, and other properties, as well as no pollution or harm to the human body and the environment. It can effectively control the plastic shrinkage of concrete and

It can effectively control the generation and development of non-structural cracks, such as plastic shrinkage in concrete and mud mortar, effectively hinder the segregation of aggregates and the formation of settlement cracks, and improve the quality of concrete.

Cracks improve concrete’s seepage and impact resistance and increase its toughness and wear resistance, extending the building’s life.

The life span of the building can be extended.

PVA Fibre

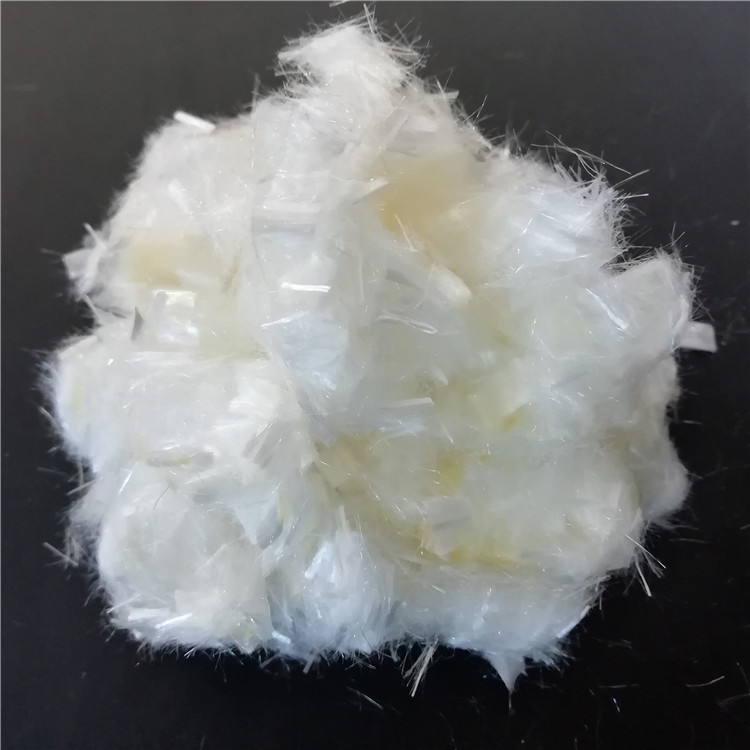

Technical principle: The product can be dispersed uniformly in concrete through special treatment and can continue to exert its effect for a long time.

The fibers are chemically grafted and physically modified, and their surface is rough and porous, which dramatically improves the bonding force between them and the cementitious material.

The fibers are chemically grafted and physically modified. High-strength and high-mode polyvinyl alcohol fiber can be added to the concrete base material and quickly and easily mixed with the mortar and concrete material.

The fibers can be quickly and easily mixed with the mortar and concrete materials. As the fibers are fine and have a large surface area, they can form a chaotic

support system inside the concrete, effectively controlling the generation and development of non-structural cracks such as plastic shrinkage of concrete and cement mortar.

PVA Fibre

Effectively hinder the segregation of aggregates, impede the formation of settlement cracks, and improve the concrete’s seepage and impact resistance.

Increase the toughness and abrasion resistance of concrete to prolong the life of the building and play the role of secondary.

Manufacturing method: Polyvinyl alcohol high-strength high-modulus fiber (PVA) is the primary raw material of polyvinyl alcohol, which is dissolving, spinning, heat-setting, cutting, cutting, and cutting.

Silk, heat-setting, cutting, and packing are made of high-strength, high-modulus fiber. It is widely used and can be applied to various reinforcing materials.

It is widely used in building materials, safety nets, and industrial textiles.

PVA Fibre

Quality Indicators.

Product Performance

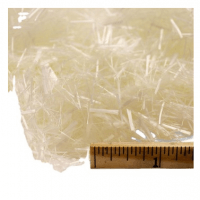

1、Appearance: slightly yellow

2、High strength and low elongation

3, Acid and alkali resistance: under high temperatures for a long time, the loss of strength is lower than in other fibers.

4, light resistance: When exposed to the sun for a long time, the fiber strength loss rate is much lower than that of other fibers.

5. Corrosion resistance: Fiber can be buried in the ground for a long time without mold, rot, or moth.

6, dispersion: the fiber is not sticky, has good dispersion in water, and has a good affinity with cement.

Main uses.

1、Cement reinforcing material. The fiber has high strength and good dispersing properties, is harmless and non-toxic, and has the characteristics of anti-corrosion, anti-insect moth, sunlight resistance, etc. It can be widely used in cement products and road construction, water conservancy projects, etc.

(1)Replacing asbestos to make high-strength cement products

(2)It can be used in road construction, especially in the construction of high-grade highways.

(3) Filament bundles can be used instead of steel bars in the construction of water conservation projects.

(2) It can be made into high-strength ropes, safety nets, and high-strength industrial textiles.

3、It can be made into a tire cord, rubber reinforcing materials for conveyor belts, fire hoses, braided hoses, etc.

Fibre for textiles is not the same as that for concrete; if you ask for other uses, you can ask to give the technical parameters of use. The way and so on.

Packaging and storage and transport precautions: 10kg, 180kg/bag. Can be compressed, can be transported on pallet. Store in cool, dry and ventilated warehouse.