Concrete lathering representatives are additives made use of in the production of light-weight concrete, likewise called cellular concrete or oxygenated concrete. These representatives introduce steady bubbles or foam right into the concrete blend, lowering its thickness and offering insulation and acoustic homes. Foaming representatives are typically included in a slurry of concrete, water, and sometimes aggregates prior to putting.

Lightweight: Reduces the total weight of the concrete, making it less complicated to manage and suitable for applications calling for decreased structural load.

Insulation: Supplies thermal insulation, which can help reduce power prices in buildings.

Acoustic Residences: Boosts audio absorption and decreases noise transmission with wall surfaces and floors.

Workability: Improves the workability of the mix, allowing for easier pumping and placement.

Sturdiness: Can improve freeze-thaw toughness as a result of the air entrapped within the matrix.

Flexibility: Appropriate for a range of applications consisting of floor covering, roof, and wall surface building.

Toughness: Relying on the application, lathered concrete can accomplish appropriate compressive stamina in spite of its lower density.

Construction: Used in creating lightweight walls, floors, and roofs where insulation and soundproofing are required.

Backfill: Ideal for backfilling operations around pipelines and in locations where conventional backfill materials might be too heavy.

Gap Filling: Filling up cavities and gaps in existing structures without adding significant weight.

Green Building: Contributing to sustainable building methods due to its lower symbolized energy and capacity to boost power efficiency.

Bridge Building and construction: For bridge decks and various other components where reduction in dead tons is important for architectural integrity.

Repair: Useful out of commission and replacing deteriorated areas of concrete frameworks without the demand for extensive demolition.

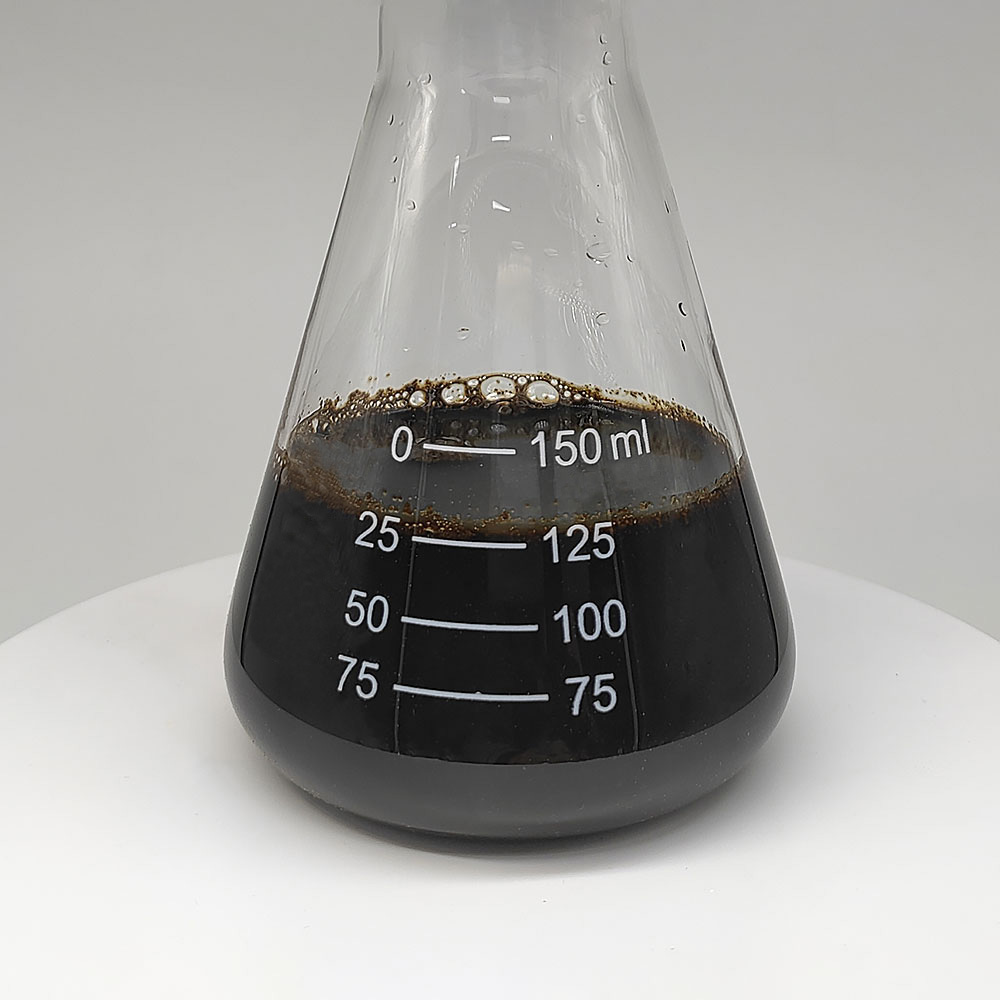

HML-B Foaming agent

Package of Concrete Foaming Agent

25kg/barrel, 200kg/barrel, 1000kg/barrel, stored at room temperature away from light, moisture and rain.

FAQs of Concrete Foaming Agent

Q: What types of lathering agents are typically used?

A: Usual kinds consist of protein-based lathering representatives, which are originated from all-natural healthy proteins, and artificial frothing agents made from petrochemicals.

Q: How do lathering representatives impact the toughness of concrete?

A: While foaming agents lower the density of concrete, appropriate formulation can still achieve enough stamina for particular applications. The stamina depends on the thickness and mix design.

Q: Can foamed concrete be made use of for structural functions?

A: Yes, depending on the thickness and mix layout, foamed concrete can be made use of structurally, though it's even more commonly made use of for its insulative and light-weight residential properties as opposed to high strength needs.

Q: Is foamed concrete extra expensive than routine concrete?

A: Normally, foamed concrete might cost even more due to the additional foaming representative and specialized mixing devices needed. Nonetheless, the price can be offset by reduced transport and labor costs, along with prospective savings in structure expenses due to lighter loads.

Q: Does frothed concrete have any ecological benefits?

A: Foamed concrete can use numerous environmental advantages, such as minimized energy usage during manufacturing, reduced transport discharges as a result of lighter weight, and enhanced power performance in structures because of its insulative homes.

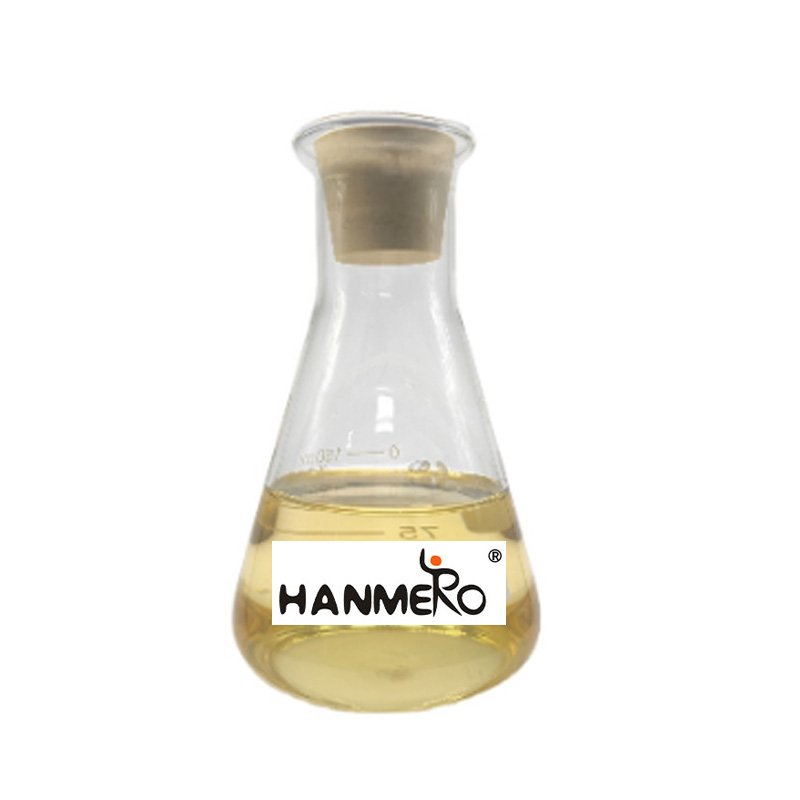

HML-C Polymer Foaming Agent

Item

Test Results

Appearance

Light yellow and transparent

Density(g/mL)

1.01

Foaming multiple

26

Settlement distance(mm)

30

pH

8.0-9.5

Dilution ratio

1:30

Operating temperature (℃)

-10-40

1) Increase the strength of the wallboard by 20%

Because of its high foam toughness, the foam wallboard made of foamed wallboard has high cell integrity, closed cell ratio of more than 90%, and spherical thin shell structure, which increases the strength of foamed concrete by more than 20% compared with foam concrete with connected foam cells.

To achieve the same design strength, foam concrete with a high closed-cell ratio can reduce density and save 10% of raw material cost.

2) To improve the thermal insulation performance of wallboards and other products

The foam wallboard made of the foaming agent has extremely high cell integrity, and the cell closure rate is more than 90%. Hundreds of millions of closed pores are formed inside the wallboard, which can seal a large amount of air, form an inert heat conduction layer, and improve the thermal insulation performance of the wallboard.

At the same time, because it has higher strength than other foamed cement with the same density when it reaches the same strength, it can reduce the density of foam concrete, thus reducing the cost and improving the performance of thermal insulation.

3) High stability

HML-C polymer foaming agent is composed of a high-performance foam stabilizer and surfactant. The foam stability is remarkable. In the wallboard production process, the foam paste stability is high, there is no mold collapse phenomenon, the foaming and workability are good, and it can fill the mold without leaving a dead corner.