Overview of Concrete Foaming Equipment

Foaming equipment, additionally known as foam generator, makes foam from a liquid solution containing a specific focus of frothing representative. Foam generator is a vital tools for producing lathered cement and foam-mixed dirt, directly affecting lightweight concrete's high quality and performance. HANMERO collection foam generator all utilize high-pressure air foaming, which has the advantages of fast frothing rate, high effectiveness, little bubble diameter, great foam security, low foam secretion and conserving lathering agent.

Features of Concrete Foaming Equipment

It can precisely manage the density and top quality of the foam, making certain that the generated foam concrete has an uniform circulation of bubbles, which not only enhances the thermal insulation efficiency of the product, but likewise boosts the architectural strength. Second of all, the equipment is very easy to run and has a high level of automation, which greatly lowers labor prices and labor intensity, while enhancing job effectiveness. Moreover, given that the foaming proportion can be readjusted, it is suitable for a range of building needs, from wall surface loading to roofing system insulation, with strong adaptability. Furthermore, using concrete frothing makers can effectively minimize the quantity of concrete used and decrease carbon discharges, which is in line with the advancement trend of eco-friendly structures. This machine is normally outfitted with an advanced mixing system to guarantee the complete blending of the combination, avoid stratification, and additionally guarantee the top quality of the project.

Applications of Concrete Foaming Equipment

HML-11 Foaming machine

Foaming machine, also called foam generator, is the equipment to make foam from aqueous solution containing a certain concentration of blowing agent. It is the key equipment for producing foamed cement and foam concrete.

A foaming machine (also known as foam-generating equipment) is the core equipment of a lightweight concrete preparation system. Its primary function is to convert the proportionally prepared foaming agent aqueous solution into standard foam through a professional process. As the key equipment for foam concrete and foamed cement production, its technical performance directly determines the core indexes such as structural strength, density distribution, and durability of the final products.

high-pressure foaming equipment adopts advanced airflow mechanics foaming technology, which has the following significant

advantages:

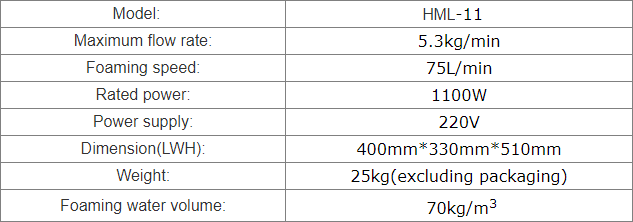

HML-11 Foaming machine

HML-11 foaming system (power 1.1kW/bright yellow)

This experimental grade equipment is designed for scientific research institutions and engineering verification needs, applicable to:

1. Building materials laboratory: This laboratory collaborates with colleges, universities, and research institutes to develop new lightweight concrete formulations.

2. Small-scale engineering applications: bath backfill, floor heating matting and other renovation projects on-site foaming operations.

3. Trial production scenario: sample preparation and small batch production for small precast component factories.

Important operation specification: Based on the thermodynamic protection mechanism, it is recommended to run continuously for ≤ 20 minutes at a time and cannot be switched on continuously for an extended period so as to ensure the service life of the equipment and the accuracy of the experimental data.